Chip-on-Glass: Everything You Need to Know

Chip-on-Glass technology is quietly revolutionizing the way embedded devices are built, offering a smarter, sleeker alternative to traditional display architectures.

If you’ve ever wondered how today’s most compact, responsive, and visually polished interfaces come to life, you’re in the right place.

In this guide, we’ll break down everything you need to know about Chip-on-Glass displays: how they work, why they matter, and how they can give your next product a powerful edge.

Chip on Glass: What is It?

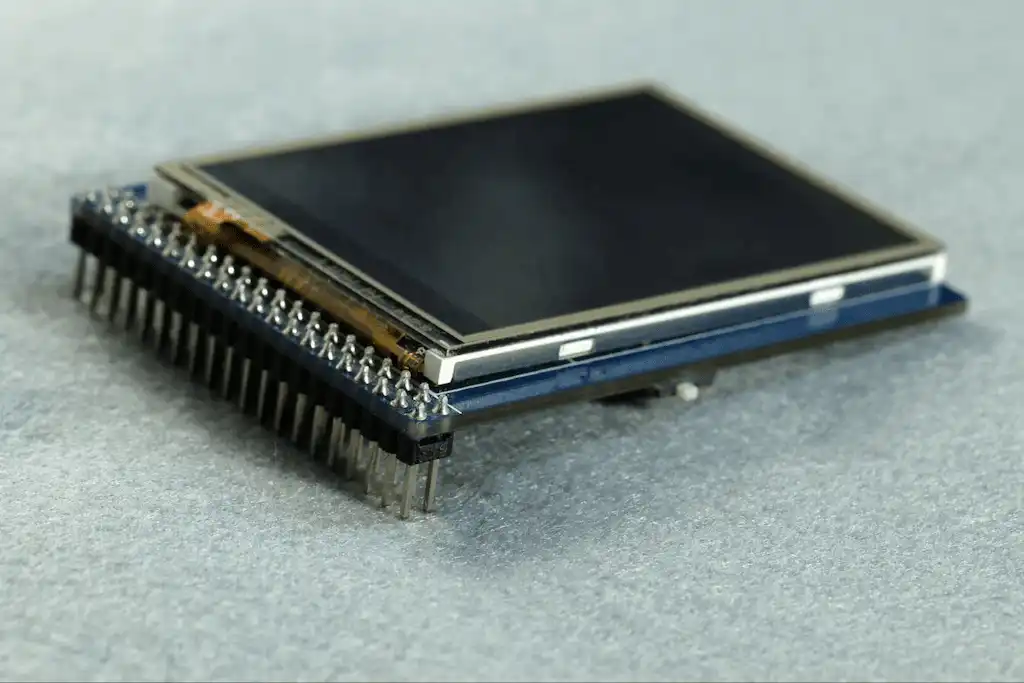

Chip-on-Glass (COG) is an advanced display integration method where the driver IC is mounted directly onto the glass substrate of the LCD.

This streamlined architecture reduces the number of physical components required and results in a thinner, more compact module.

The approach was developed in response to increasing demand for space-saving display technologies in modern embedded systems, particularly in devices where form factor, durability, and cost efficiency are paramount.

COG technology eliminates the need for an external PCB or flexible printed circuit to house the driver IC, simplifying both the display design and the manufacturing process.

As a result, COG displays have gained popularity in industrial, medical, automotive, and consumer electronics applications where reliability, performance, and a clean appearance are critical.

Chip on Glass: How Does it Work?

In a COG display, the driver chip responsible for controlling the LCD is directly bonded onto the glass surface of the display panel.

This is typically achieved using a method called gold wire bonding or Anisotropic Conductive Film (ACF) bonding, each providing a secure and highly conductive connection between the IC and the transparent electrodes on the glass.

Once bonded, the IC is sealed with protective materials to safeguard it from environmental stressors such as moisture, dust, or shock.

This integrated setup drastically reduces the length of signal paths between the controller and the pixel array, which in turn improves signal integrity, reduces latency, and minimizes electromagnetic interference (EMI).

The display is then completed by layering a backlight unit, polarizers, and optional touch panels (capacitive or resistive).

The final product is a standalone display module that can be quickly integrated into end-user applications with minimal supporting circuitry, often just a serial connection and a power supply.

This architecture allows for greater electrical efficiency, higher reliability, and a more streamlined form factor than traditional display setups.

Chip on Glass Features

- Slim Profile: With no external PCB for the driver IC, COG modules offer a compact, low-profile design ideal for space-constrained applications.

- Integrated Driver IC: The driver chip is bonded directly to the glass, which reduces complexity and saves board space.

- Fewer Interconnects: Minimal wiring and connections between display and control logic reduces potential points of failure and EMI issues.

- Improved Electrical Performance: Shorter signal paths translate to faster communication and lower signal degradation.

- Touch Compatibility: Supports both resistive and capacitive touchscreens for interactive applications.

- Design Flexibility: Available in a wide range of display sizes, resolutions, and aspect ratios to fit specific user interface requirements.

- Lightweight Construction: Ideal for handheld and portable devices where weight is a consideration.

- Clean Aesthetics: Absence of a bulky driver board or exposed components results in a modern, polished look.

How is COG Different from Chip on Board (COB)?

While both COG (Chip on Glass) and COB (Chip on Board) technologies are used to drive LCD modules, they differ significantly in structure, scalability, and end-use suitability.

COG (Chip on Glass) integrates the driver IC directly onto the glass panel of the display. This allows for a compact and streamlined form factor that eliminates the need for a separate PCB to host the chip.

The result is a slimmer module with fewer components, reduced signal interference, and improved electrical performance.

On the other hand, COB (Chip on Board) involves mounting the IC onto a printed circuit board (PCB), typically near the LCD.

The chip is then encapsulated with epoxy (usually a black resin “blob”). While this method is cost-effective for low-volume production and prototyping, it introduces extra bulk and limits design flexibility.

In essence, COG is the go-to for modern, high-integration applications, while COB remains useful in simple or development-focused environments.

How to Choose the Right Chip on Glass (COG) display?

- Display Size and Resolution: Consider the physical space in your product and the level of detail required. COG displays are available in a wide range, from small 2.8″ touchscreens to large 10″+ panels with high pixel density.

- Touch Interface Type: Choose between resistive touch (cost-effective, works with gloves/styluses) and capacitive touch (multi-touch, higher responsiveness, glass cover).

- Communication Interface: Ensure compatibility with your host MCU or system. Common interfaces include UART, RS-232, RS-485, SPI, and I²C.

- Environmental Considerations: If the device will operate in industrial, outdoor, or medical environments, check for wide temperature ranges, humidity tolerance, and EMI shielding.

- Design Toolchain: Opt for a display that supports an intuitive GUI builder to reduce development time.

- Certifications and Compliance: For regulated industries, be sure your display meets relevant standards (e.g., ISO, CE, RoHS, FDA).

Launch Faster with Proculus Technologies!

Bringing a product to market shouldn’t be slowed down by complex display integration. At Proculus, we specialize in helping developers cut time-to-market through intuitive, high-performance display modules powered by Chip-on-Glass (COG) technology.

Our UART TFT LCD modules are engineered for simplicity! Using just a few serial commands, you can deploy fully interactive graphical interfaces without needing to write low-level display drivers.

Every module comes ready for seamless integration, equipped with touch support, flash storage, and a suite of prebuilt GUI elements.

With our free development environment, you can create, test, and deploy a professional-grade user interface in hours instead of weeks.

Conclusion

Chip-on-Glass technology is a gateway to smarter, more efficient product design.

By eliminating unnecessary hardware layers and simplifying the display interface, COG displays empower engineers to build compact, reliable, and feature-rich devices with less complexity.

As demand grows for connected, intelligent, and user-friendly embedded systems, COG displays are becoming a standard across medical, industrial, consumer, and automotive markets.

We can provide all the hardware, tools, documentation, and support you need to bring your ideas to life quickly and confidently.

English

English