LCD Display Issues: How to Diagnose and Fix Problems

LCD displays are the backbone of countless devices. Their versatility, clarity, and efficiency make them the default choice for engineers worldwide.

However, like any technology, LCDs are not flawless. Over time, stress factors such as backlight aging, unstable power, or environmental exposure can compromise performance.

Recognizing these problems early is crucial. A blurred image, intermittent failure, or even a blank screen often signals an underlying issue that, if ignored, may lead to costly downtime or full system failure.

By understanding the most common LCD display issues, engineers can take proactive steps to troubleshoot, maintain, and decide when it’s smarter to repair or replace.

This guide explores the leading causes of LCD failures, practical solutions, and preventive maintenance strategies, all aimed at keeping your systems running reliably for years to come. Keep reading!

Deciding between repair and replacement depends on the severity of the issue, the age of the display, and the criticality of the application.

Repair makes sense when:

Deciding between repair and replacement depends on the severity of the issue, the age of the display, and the criticality of the application.

Repair makes sense when:

Common Causes of LCD Display Issues

Even industrial-grade LCDs are not immune to failure. Over time, multiple stress factors can affect image quality, stability, or even render the display unusable. Understanding the root causes helps engineers diagnose problems faster, plan preventive maintenance, and decide when replacement is the best option. Here are the main issues:Backlight degradation

The backlight is one of the most common failure points in LCDs. LEDs gradually lose brightness after thousands of hours of operation, with typical lifespans between 30,000 and 100,000 hours, leading to dim screens and reduced contrast. Excessive heat accelerates this process, shortening lifespan. When backlight degradation occurs, the display may still function electrically, but usability drops sharply in bright environments.Connection failures

LCDs rely on multiple connectors (ribbon cables, zebra connectors, or solder joints) to transfer signals between the panel, driver board, and power supply. Over time, vibrations, dust ingress, or simple wear can loosen these connections. The result is flickering screens, missing segments, or intermittent operation. Reseating or replacing connectors often restores stability.Environmental stress

Humidity, temperature extremes, and exposure to UV light are common environmental stressors. Moisture can cause condensation inside the panel, leading to hazy or blurred images. Heat accelerates material fatigue, while cold conditions slow liquid crystal response times. Continuous exposure to direct sunlight can cause degradation in plastic components, which in turn cause discoloration and brittleness. Outdoor and industrial applications require displays specifically designed to withstand these stresses.Power fluctuations

Unstable power supplies or voltage spikes can cause sudden display failures or long-term degradation of electronic components. Inconsistent current delivery may result in random resets, image noise, or complete blank screens. Protecting displays with regulated power and surge suppression is critical in environments with unreliable electrical infrastructure.Driver or controller faults

The driver IC and controller board manage how signals are translated into visual output. Firmware bugs, aging semiconductors, or overheating can introduce display anomalies such as missing characters, distorted graphics, or delayed response. In many cases, updating firmware or replacing the controller board resolves these issues.Physical stress

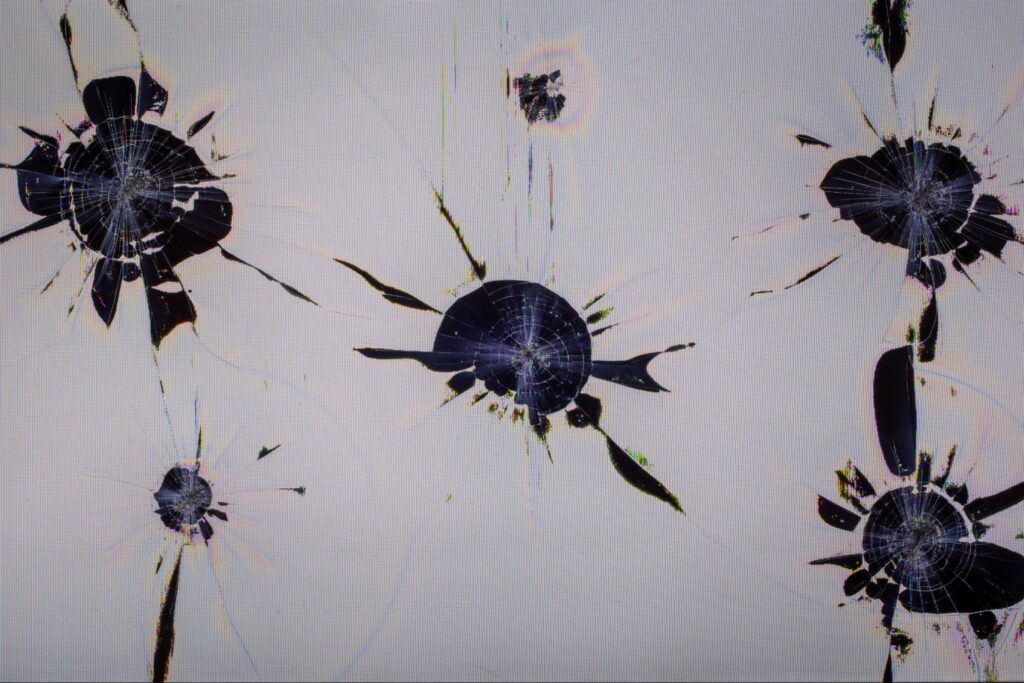

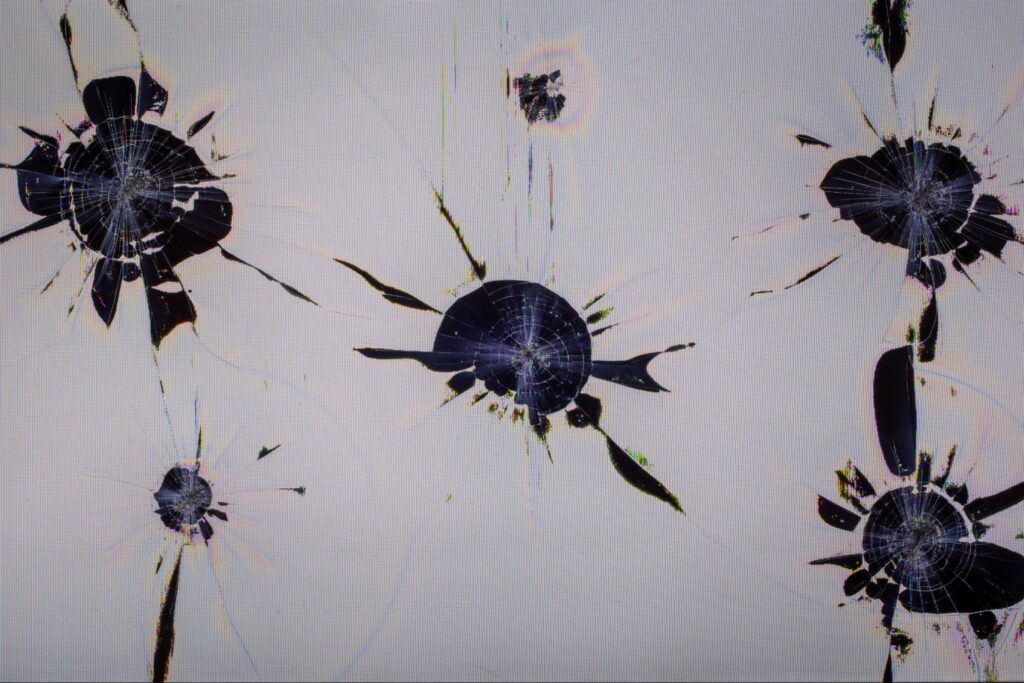

LCD panels are inherently fragile. Mechanical shocks, bending, or direct pressure can crack substrates, damage liquid crystal layers, or break solder joints. Even small physical stresses may cause permanent defects such as dead pixels or non-uniform brightness. Protective housing and careful handling during assembly are essential to prevent this type of damage.How to diagnose LCD Display Issues

Accurate diagnosis is the first step toward resolving display failures. Without a structured approach, engineers risk replacing good components or overlooking the true source of the problem. Effective troubleshooting balances visual inspection, power verification, and functional testing. Here’s how to diagnose LCD display issues:Start with a Visual Check

Examine the panel for cracks, condensation, or discoloration. Look closely at connectors, ribbon cables, and solder joints for signs of wear or damage. Physical stress and loose connections are some of the simplest but most common culprits.Verify Power Supply Stability

Use a multimeter or oscilloscope to confirm voltage levels and ripple. Power fluctuations are often responsible for flickering, random resets, or complete screen blanks. Ensuring a regulated, stable supply eliminates one of the most frequent root causes.Test Backlight and Brightness

If the image is extremely dim or invisible, check the backlight circuit. A failing LED array or inverter board often causes otherwise functional displays to appear dead.Isolate Hardware from Software

Swap cables, use alternate controller boards, or run test firmware to determine whether the issue lies in the display hardware or the system software driving it. This separation avoids unnecessary hardware replacement.Check Environmental Factors

Consider the operating environment, like extreme temperatures, humidity, or dust may degrade performance. Replicating the display in controlled conditions can reveal whether environmental stress is at fault.Run Diagnostic Patterns

Applying standard test images or pixel-refresh patterns helps identify ghosting, stuck pixels, or uneven backlighting. This is particularly useful for detecting subtle defects that worsen over time.Preventive Maintenance for LCD Displays

Preventive maintenance is essential to extend the operational life of LCD displays, especially in industrial or outdoor environments where conditions are demanding. The goal is to reduce wear, avoid unexpected downtime, and preserve image quality over thousands of hours of use. Key practices include:- Environmental control: Keep displays away from excessive heat, humidity, and dust. Thermal cycling and moisture are leading causes of premature LCD degradation.

- Regular cleaning: Use non-abrasive, anti-static wipes and appropriate cleaning agents. Harsh chemicals or rough cloth can damage polarizers and coatings.

- Power management: Avoid driving the backlight at maximum brightness continuously. Using adaptive brightness controls reduces power consumption and extends LED lifetime.

- Stable power supply: Ensure regulated input voltage and surge protection. Inconsistent power delivery is a common trigger for flickering, ghosting, or controller failures.

- Scheduled inspections: Periodically check cable connections, mounting integrity, and signs of optical layer delamination. Addressing minor issues early prevents costly replacements later.

When to Repair vs Replace an LCD Display

Deciding between repair and replacement depends on the severity of the issue, the age of the display, and the criticality of the application.

Repair makes sense when:

Deciding between repair and replacement depends on the severity of the issue, the age of the display, and the criticality of the application.

Repair makes sense when:

- Issues are localized, such as a damaged backlight, faulty inverter, or loose ribbon cable.

- The display is part of an expensive system where downtime must be minimized.

- Replacement panels are hard to source due to legacy equipment constraints.

- The display has multiple symptoms (e.g., low contrast, image retention, failing backlight simultaneously).

- The unit is reaching or past its rated service life, making further repair uneconomical.

- Modern replacements offer higher efficiency, sunlight readability, and longer lifespans, delivering better ROI over time.

Proculus Tech Solutions for Reliable Displays

At Proculus, we design and manufacture next-generation UART, Android, and HDMI display modules that address the most common challenges engineers face with traditional LCDs. Our modules are built for long operating life, high visibility, and simplified integration. With our free UnicView Studio software, developers can design professional GUIs without writing a single line of code, reducing project complexity and accelerating time-to-market. Dedicated technical support and customizable options make Proculus the partner of choice for robust HMI solutions. Explore Proculus products! Browse our portfolio to discover reliable, sunlight-readable, and easy-to-integrate display solutions tailored for industrial, medical, and commercial applications!Conclusion

LCD display issues are inevitable over time, but proactive maintenance and informed decision-making significantly reduce their impact. Knowing when to maintain, repair, or upgrade allows engineers to keep systems running efficiently and cost-effectively. For businesses that cannot afford downtime, adopting robust, modern display modules, like those from Proculus, ensures long-term performance, reliability, and customer satisfaction.

Category:

Author:

Client:

Date:

Related products

PHP Code Snippets Powered By : XYZScripts.com

English

English