How to make a display: Everything you need to know

How to make a display: Necessary materialsS

Creating a reliable and high-performing display system starts with selecting the right components. Each item plays a crucial role in ensuring smooth operation, visual clarity, and long-term durability. Here’s a breakdown of the core materials required:- Display Panel (TFT LCD, OLED, or e-paper): Choose based on your application’s demands for resolution, brightness, color depth, and viewing angles. For most embedded systems, a TFT LCD strikes a balance between cost, functionality, and ease of integration.

- Microcontroller or Processor: Select a controller compatible with your display and interface requirements. Popular options include STM32, ESP32, and Raspberry Pi. Consider processing power, available GPIOs, and memory capacity.

- Power Supply: Provide stable and regulated voltage (typically 3.3V or 5V). Power fluctuations can cause display flickering or complete failure. Include protection features like reverse polarity and over-voltage protection when possible.

- Communication Interface: Depending on your module, this could be UART (simple and ideal for Proculus displays), SPI (fast, low-pin count), I2C (multi-device), or HDMI (high-bandwidth multimedia). Match the protocol to your hardware and speed needs.

- Display Drivers & Firmware Libraries: These manage how your microcontroller communicates with the display. Reliable, well-documented drivers save countless hours during development.

- User Interface Design Tools: Software like UnicView Studio lets you design responsive, user-friendly graphical interfaces without deep programming expertise—ideal for speeding up HMI development.

- Wiring, Connectors & Mounting Accessories: Ensure proper cable management and secure physical assembly. A robust mechanical setup prevents disconnections and improves overall system reliability.

- Optional Peripherals: Depending on your application: capacitive/resistive touch panels, sensors, enclosures, Wi-Fi/Bluetooth modules, or audio components can be integrated.

How to make a display: Step by step

Creating a display is about delivering a seamless user experience through both hardware and UI design. Below is a clear, practical sequence that reflects modern embedded design best practices:Define the purpose of the display

Start with clarity. What role will the display serve? A control panel in industrial equipment? A readout on a medical device? Each scenario demands different levels of responsiveness, brightness, resolution, and user input. Defining purpose early helps specify the required features, such as sunlight readability, capacitive touch, or multilingual support. This foundation ensures the rest of your design is aligned and efficient.Choose the right type of display

Not all displays are created equal. For embedded projects, UART TFT LCDs offer fast integration with minimal development overhead. If you need advanced features like video playback or multitasking, Android-based LCDs are a better fit. For high-resolution content or multimedia, HDMI-enabled modules provide plug-and-play versatility. Consider size, viewing angle, power consumption, and environmental durability to match your display to your application.Plan the layout

An effective interface isn’t just attractive—it works intuitively. Use a grid-based approach to position buttons, text, and visual indicators where users naturally expect them. Think about contrast, color coding, and font legibility. Design for touch input with adequate spacing to prevent mis-taps. With UnicView Studio, you can rapidly prototype layouts and iterate without deep programming, making UI design both accessible and precise.Test the display

Testing is where ideas meet reality. Connect your display to the host system and power supply, then begin functional checks. Verify that communication protocols are working (e.g., UART message exchange), ensure that graphics render correctly, and test responsiveness of any input elements. Environmental tests, such as vibration, temperature, or EMC, may be necessary for commercial or industrial applications. Debug early, often, and with a systematic checklist.Use and evaluate

Once your display is live in a target environment, observe how it performs under actual use. Is the interface intuitive? Does it update in real time? Are users making mistakes? Feedback from stakeholders, whether factory workers, customers, or QA engineers, can reveal gaps in design or usability. Iterate based on this feedback. In embedded systems, even small UX improvements can lead to big operational gains.What is a display for?

A display is the interface between machine logic and human intention. In embedded systems, displays serve three primary purposes:- Visualization of Information: From sensor data to process feedback, the display converts invisible system states into readable, real-time data the user can act on.

- User Interaction: Through touch, buttons, or other input methods, displays allow users to navigate settings, initiate actions, and control workflows—without needing to understand the underlying code

- Brand and Product Experience: The quality and clarity of your display directly influence how end-users perceive your product. A professional interface communicates trust, modernity, and attention to detail.

What makes a display attractive?

An attractive display is one that, beyond looking good, performs well under real-world conditions while providing a seamless user experience. Here’s what contributes to making a display both appealing and effective:

An attractive display is one that, beyond looking good, performs well under real-world conditions while providing a seamless user experience. Here’s what contributes to making a display both appealing and effective:

- High Readability: Clear text and sharp visuals under various lighting conditions, including sunlight-readable brightness and wide viewing angles.

- Responsive Touch Interface: Smooth interaction with capacitive or resistive touch technology that accurately tracks user input without lag or calibration issues.

- Intuitive UI Design: A logical interface layout that minimizes the learning curve. Buttons, menus, and icons should be where users expect them—simple, functional, and clean.

- Consistent Visual Language: Use a coherent color palette, readable typography, and uniform element sizing. These details enhance professionalism and brand recognition.

- Feedback and Transitions: Visual cues like button animations or loading indicators confirm that the system has registered an action, boosting user confidence.

- Hardware Build Quality: Crisp resolution, no flicker, uniform backlighting, and a durable front panel, all contribute to long-term satisfaction and usability.

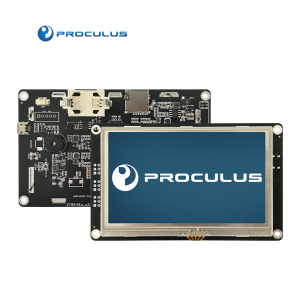

Bring your display to life with Proculus Technologies

Proculus Technologies empowers developers with ready-to-use smart display modules that dramatically reduce time-to-market and development complexity. Our UART TFT LCD modules are engineered for seamless integration, communicating through a simple, five-command protocol that even beginners can master. Paired with UnicView Studio, our displays allow you to design responsive, professional user interfaces, without writing a single line of graphics code. Whether you’re designing a product prototype or mass-producing industrial equipment, Proculus offers the performance, stability, and support engineers rely on. Explore our UART TFT LCD Modules and discover how simple embedded display development can be!Conclusion

Making a display is both a technical challenge and a creative opportunity. With the right components and workflow, your display becomes a powerful medium for interaction, one that’s intuitive, efficient, and tailored to your specific use case. Proculus Technologies streamlines every stage of this journey. From modular UART LCDs to intelligent development tools, we equip engineers and innovators with the resources they need to build robust, elegant HMI solutions faster than ever. Ready to bring your vision to life? Let’s build it together with Proculus.

Category:

Author:

Client:

Date:

PHP Code Snippets Powered By : XYZScripts.com

English

English